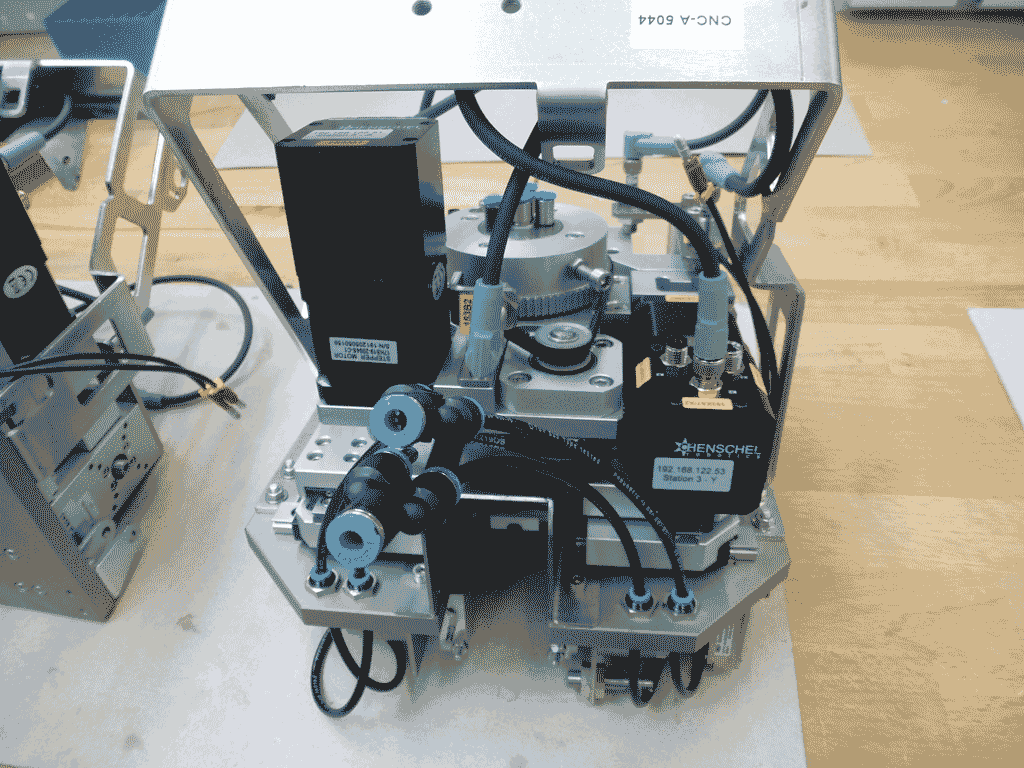

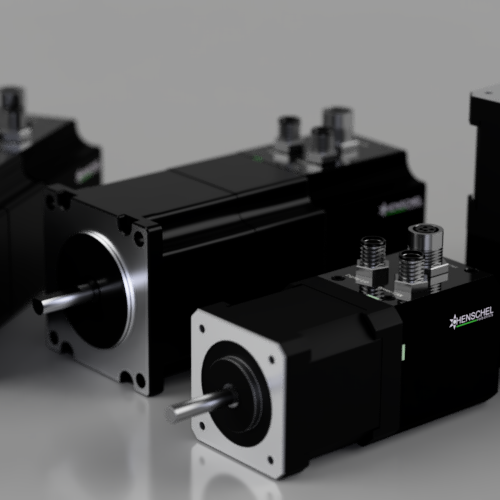

HDrive23-ETH-i with 2 Nm stall torque

We are pleased to announce that the HDrive23-ETH-i units are now ready to ship. The concept is similar to the HDrive17-ETH-i, but it features a 57mm x 57mm motor with almost double the stall torque.

Both the HDrive23-ETH-i and HDrive17-ETH-i share the same core software and web GUI, so there is no need to differentiate between them. The firmware is compatible with both drives, and the new drive benefits from over 5 years of firmware development experience.